- This is PANASIA

- Business locations

- ESG Management

- History

- Smart PANASIA

About

About

Check PANASIA introduction,

ESG management, and History

information

- Energy Solutions

- Air Solutions

- Water Solutions

Eco-friendly Solution

Eco-friendly Solution

About Global environmental

regulation, Hydrogen business,

Air quality, and Water quality

environment solutions

- Product Service

- Service Network

- Customer Service

Customer Support

Customer Support

Check the Panasia’s

after service

- About

- Eco-friendly Solution

- Customer Support

- Media

NEWS

PANASIA’s first main product, hydrogen generation system,

PanaGen developed with 100% domestic technologies

Many have taken note of the recent moves by PANASIA, a Busan based shipbuilding material manufacturer who has been pursuing new breakthroughs in the hydrogen

production area. The new product that has been catching their attention is a hydrogen extractor prototype that was installed in KITECH, located in Gangseo-gu Busan,

and that is currently in test operation.

PANASIA (CEO Lee Soo Tae), a shipbuilding materials manufacturer, is one of the best known Busan-based companies seeking its future in the hydrogen industry.

But unlike other companies, which have tended to explore opportunities in hydrogen consumption and utilization, PANASIA is committing itself to the hydrogen

production area, hoping to making a great quantum leap on its own. Although it is going into battle with major global companies, this Busan-based company is

already proudly showing off significant accomplishments in this area.

Located in Busan’s Mieum industrial complex, PANASIA signed an MOU for hydrogen extraction facilities investments with the city of Daejeon in April 2020, and has

installed a prototype in KITECH (located in Gangseo-gu, Busan) that has started test operation, thus taking a step toward becoming a main hydrogen company.

Early entry to the hydrogen sector in the coming era of hydrogen industry

PanaGen is a lightweight and small-scale reformed hydrogen facility

Localization of catalyst technology, improved performance and price competitiveness

Successfully extracted 99.999% pure hydrogen

CEO Lee Soo Tae’s leadership is the driving force behind technological

development

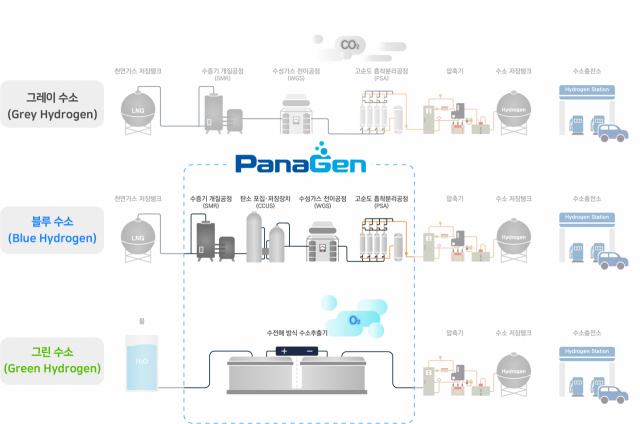

Rough classification of hydrogen based on production methods, Provided by PANASIA

It is no accident that PANASIA is looking to find its future in the hydrogen industry. This is mainly due to the company’s history of growing rapidly amidst the global

environmental regulations for the past several years. As the IMO(International Maritime Organization) took a firm step toward stricter regulation of the sulfur oxides

generated by ships, PANASIA, the developer of scrubber, sulfur oxides reduction device for ships, was soon flooded with product orders from around the world.

In 2018, revenue was 64.7 billion KRW, and reached 328.4 billion KRW in 2019 and 355.8 billion KRW in 2020. As a PANASIA insider commented, “Monitoring

the global eco-friendly trends, we learned that the future of the hydrogen industry is promising as a next generation eco-friendly industry.” Also, global companies

began to enter the hydrogen market one by one, and the Korean government expressed its interest in promoting the hydrogen industry.

Pioneering the hydrogen industry, PANASIA has developed its first product, PanaGen, a hydrogen extractor that produces hydrogen by reforming natural gas.

PanaGen is a reformed hydrogen production facility that separates and extracts hydrogen from LNG. Currently, domestic charging stations use hydrogen which

is generated as a by-product from the petrochemical manufacturing process; PanaGen’s reformed hydrogen can offer reduced distribution costs, excellent

eco-friendly merits and high productivity.

The biggest advantage is that if you install PanaGen, you can immediately start extracting hydrogen by using the existing natural gas supply chain. As a spokesperson

for PANASIA put it, “The reformed hydrogen extractor can be lightweight and miniaturized, and this is the biggest of its advantages,” adding that “reformed hydrogen

from LNG can become a stepping stone to achieving the hydrogen economy.”

PANASIA’s first prototype is a hydrogen extractor that can produce 30N㎡/hour through reforming natural gas. The core technologies for the hydrogen generation

system, including PSA(pressure swing absorption) and WGS(water gas shift), have been developed with 100% domestic technologies. Catalyst technology, for which

Korean companies used to rely on imports, was successfully localized, improving the performance and price competitiveness. In addition, in the test period from July 2020

to September 2020, PANASIA successfully generated 99.999% high-purity hydrogen. The product to be delivered to hydrogen charging stations in Daejeon in early 2022

can produce 250N㎡/hour. This is equivalent to filling up 20 large buses with the 500kg produced daily.

Another advantage of PanaGen is that safety is always the highest priority during the entire hydrogen production process, which is remotely monitored. PANASIA can

perform real-time remote monitoring of all processes of hydrogen charging stations, and control their facilities accordingly.

PanaGen is quickly becoming a next-generation product as many applications are found in building hydrogen generation system development, building/power plant fuel

battery system sales and so on. The movement is closely related to increases in the renewable energy produced by power plant operators as well as the various benefits

granted to eco-friendly buildings by the self-governing local organizations and so on. As the prototype of PanaGen is about to be launched in the market, building hydrogen

generation system development will be completed in the near future.

PANASIA has achieved blue hydrogen by developing a Carbon Capture, Utilization and Storage (CCUS). This is significant in the sense that PANASIA successfully overcame

major weakness of reformed hydrogen made from LNG, which is classified as grey hydrogen due to its generation of CO2, which will lead to significant competitiveness.

In particular, the product can maximize efficiency, reduce the original costs and support lightweight availability as it involves the collection of gas throughout the entire

processes of exhaust gas. In addition to the CCUS, PANASIA will apply carbon capture technologies to ship/plant markets that will be under stricter regulation of CO2 emissions.

A CCUS for ships being made by PANASIA has already been designed and passed a test in barge ships. By around August of this year, it should be successfully approved

by the vessel owner, and ultimately commercialized by the end of the year.

Moreover, PANASIA has started developing water electrolysis based hydrogen generation system that produce hydrogen by using water in the last stage, called green

hydrogen. A water electrolysis hydrogen generation system yields no environmental byproducts such as CO2 and the like, and thus is expected to play a significant role in

opening a new chapter for the future of PANASIA. As a PANASIA insider commented “Within the short term, we will find a strategic partner or proceed with M&A to

improve our hydrogen development abilities.”

This bold move by PANASIA is backed up by the leadership of CEO Lee Soo Tae, who has been well known for his work to conquer the market through aggressive

technological development since the company was established in 1989. Lee Soo Tae has been at the frontier to assess the global eco crisis and implement

an eco-friendly product portfolio for the company, as well as making a transition to smart factories amidst the 4th industrial revolution. The move to enter

the hydrogen market was possible because CEO Lee Soo Tae took the initiative.

In addition to its own efforts, PANASIA is optimistic about getting support from the government and the self-governing local organizations. Despite the government’s

announcement of a transition to a hydrogen economy, the production cost for hydrogen is much higher than for other power sources due to the limitations of current

technologies. Consumers always look for the lower prices offered by fossil fuel. PANASIA takes the position that it is critical to prepare a supply plan for possible future

demands led by government policy. In particular, as much of the hydrogen supplied in Korea is imported from Japan and the like, from the perspective of energy

independence, it is critically important to promote and support domestic hydrogen suppliers.

But unfortunately for PANASIA and other Busan companies exploring the hydrogen frontier, Busan has not been as willing to promote the hydrogen economy as other

self-governing municipalities. First of all, Busan only has two hydrogen charging stations, while smaller cities such as Ulsan or Changwon have many more. This means

that local companies trying to make new breakthroughs in the hydrogen industry will be limited in their hydrogen infrastructure use or tech development or sales/marketing.

After developing the first product, PanaGen, PANASIA had to pursue tech cooperation or sales with other cities and provinces, such as signing an MOU with the city of

Daejeon to deliver the product, mainly because there was no demand in Busan. If Busan does not support the expansion of the hydrogen industry in a timely manner,

it is possible that local companies trying to break into this new field will have to find new homes elsewhere.

Reporter Kim Yeong Han, kim01@busan.com